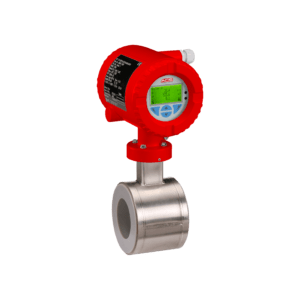

Fluxicont® FS4

Flow switch for general applications Monitoring of flow and temperature in liquids

- Short response time

- Wareless

- Display and operating on site improofes operator comfort

Description

The Fluxicont FS4 is an electronic flow resp. temperature switch for monitoring, control as well as continuous measurement of flow and temperatures in liquids.

Due to the device construction with flow velocities from 3cm/s to 300cm/s , process temperatures from –20°C to +110°C, process pressures up to 40bar, process material stainless steel V4A as well as the availability of industrial standard process connections like thread ISO 228-1 thread ANSI NPT – on request and thread ISO 225-1 M18x1,5 for adapter – on request the device is especially suitable for the use for monitoring cooling water circulation systems of pumps, turbines, compressors and heat exchangers, for monitoring pump functionality, for dry run protection for pumps, for leak monitoring in process lines, monitoring lubrication systems and filter monitoring in the beverage industry.

The flow switch is suitable for demanding measuring requirements.

Due to its high accuracy and the high flexibility of configuration, the Fluxicont FS4 can be suited a wide variety of applications.

The robust design and the high-quality workmanship turns the device into a very high quality product, which even the most adverse environmental conditions cannot affect, whether the lowest temperatures when used outdoors, extreme shock and vibration or aggressive media.

A captive laser marking of the type label ensures the identifiability throughout the entire lifetime of the device.

Obviously is the optional marking of a measurement point designation resp. TAG, a customer label or of a neutral type label, of course also per laser marking.

A LABS-free resp. silicone-free version, a factory calibration with calibration certificate and a customer specific configuration resp. preset is also optionally available like a material test certificate EN10204 3.1 or factory certifications for drink water resp. food suitability.

Customer specific special versions can be realized on request, e.g. software adaption (menu navigation, special functions, etc.), changed terminal assignment resp. connector orientation, design adaption of the user surface and special designs for the process connection.

| Sprungantwortzeit | Strömung: ≤ 6s (td = 0s / 0% >> 90% / 100% >> 10%) Temperatur: ≤ 4s |

|---|---|

| Bereitschaftszeit tOn | Strömung: ≤ 10s Temperatur: ≤ 2s |

| Gleichspannung | |

|---|---|

| Elektronik Ausgang Typ | A / B / C / D |

| Versorgungsspannung US | 10,5V…35 V DC Verpolungsgeschützt |

| Restwelligkeit UPP | ≤ 2VPP USmin ≤ US ≤ USmax |

| Stromaufnahme IIn | ≤ 100mA S1 / S2 = 0mA Iout = 22mA |

| Isolationsspannung | 500VAC (Elektrischer Anschlüsse – Gehäuse) |

| Universalspannung | |

|---|---|

| Elektronik Ausgang Typ | W |

| Versorgungsspannung US | 20V…253 V AC – 48/62Hz 20V…220 V DC |

| Leistungsaufnahme PIn | ≤ 4VA 2W |

| Schutzklasse | I (EN 61140) |

| Überspannungskategorie | II (EN 60664-1) |

| Eingang | |

|---|---|

| Messgröße | Strömungsgeschwindigkeit |

| Messprinzip | Kalorimetrisch |

| Messmedium | Flüssigkeiten |

| Messbereich | 3…300 cm/s Größte Empfindlichkeit: 3…100 cm/s Werkseinstellung: 0…100 cm/s |

| Temperaturgradient | ≥ 300 K/min |

| Schaltausgang PNP S1 / S2 | |

|---|---|

| Elektronik Ausgang Typ | A / B / C / D |

| Funktion | PNP-schaltend auf +L |

| Ausgangsspannung UOut | UOut ≥ US – 2V |

| Ausgangsstrom IL | 0mA…200mA Strombegrenzt Kurzschlussfest |

| Anstiegszeit T90 | < 30µs (RL < 3kR / IOut > 4,5mA) |

| Schaltzyklen | ≥ 100.000.000 |

| Schaltausgang Relais S1 | |

|---|---|

| Elektronik Ausgang Typ | W |

| Funktion | Relais Wechsler – schaltend auf L/+L |

| Schaltwerte | ≤ 2A ≤ 62,5VA 60W |

| Schaltzyklen | ≥ 100.000 |

| Analogausgang AOut – Strom 4…20mA | |

|---|---|

| Elektronik Ausgang Typ | B / C / D |

| Arbeitsbereich IOut | 3,8mA…20,5mA min. 3,6mA max. 22mA |

| Zulässige Bürde RL | ≤ (US – 10,5V) / 20mA |

| Messgenauigkeit | |

|---|---|

| Genauigkeit Strömung | ≤ ±5% MEV14: 5…100 cm/s, -20°C…+85°C ≤ ±10% MEV14: 100…175 cm/s, -20°C…+85°C |

| Genauigkeit Temperatur | ≤ ±1,5K (≥ 20cm/s) |

| Langzeitdrift | Strömung: ≤ ±10% MV13/Jahr, -20°C…+85°C |

| Temperaturabweichung | Strömung: ≤ ±0,4cm/s /K, -20°C…+85°C |

| Werkstoffe | |

|---|---|

| Prozessanschluss (prozessberührend) |

Stahl 1.4404 (316L) |

| Fühler (prozessberührend) |

Stahl 1.4571 (316Ti) |

| Dichtungen | FPM – Fluorelastomer (z.B. Viton®) |

| Umgebungsbedingungen | |

|---|---|

| Umgebungstemperatur | -20°C…+85°C |

| Prozesstemperatur | -30°C…120°C |

| Prozessdruck | ≤ +40bar |

| Schutzart | IP65/IP67 (EN/IEC 60529) |